Shanghai, China

+86-17317656853

inquiry@cgprotection.com

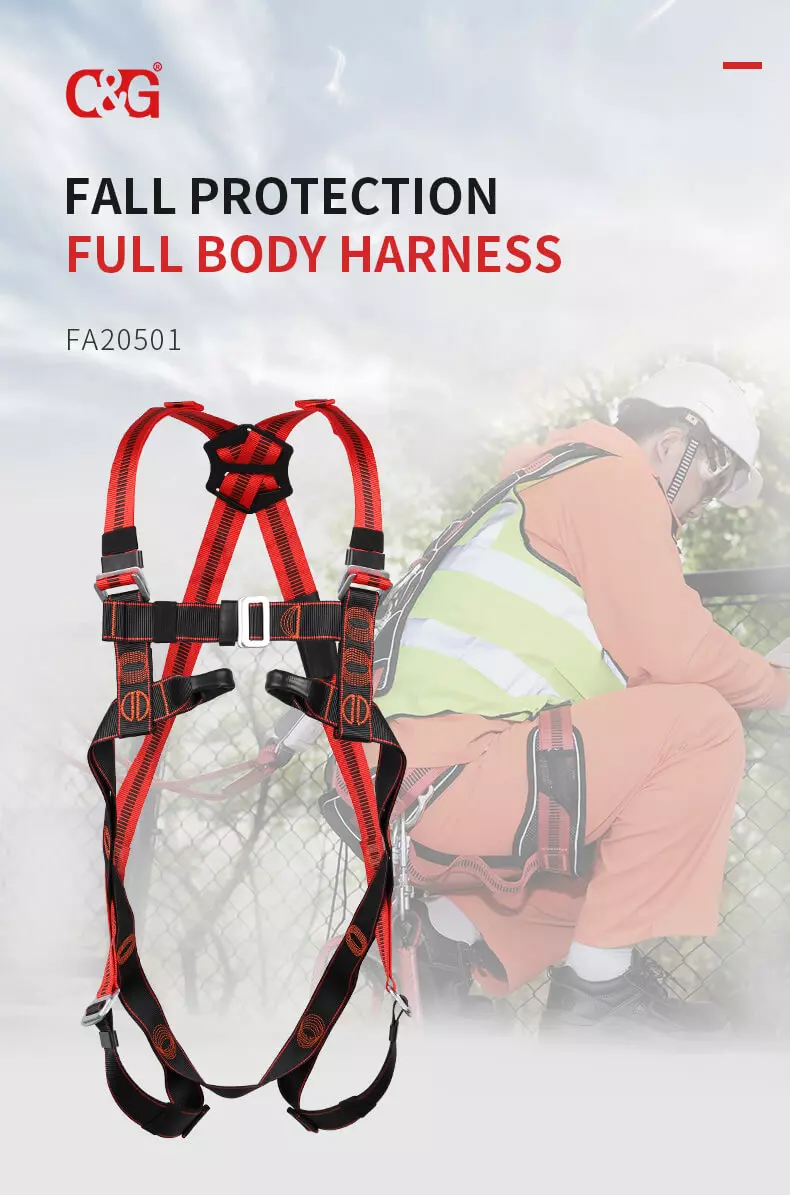

In high-altitude operations, the design and testing of fall protection systems are crucial. The design standards for safety belts and ropes, methods for testing and verification, as well as field application cases and best practices, are key to ensuring the safety of high-altitude work. This article will discuss these aspects in detail.

Material Selection

High-Strength Materials: Safety belts and ropes should use high-strength materials such as polyamide (nylon), polyester, and aramid (Kevlar) to ensure that they do not break under high loads.

Wear-Resistant Materials: To increase service life, the materials should also have good wear resistance to withstand wear and tear during long-term use.

Structural Design

Double Safety Design: Safety belts should adopt a double safety design, including a main load-bearing belt and an auxiliary belt, to provide additional safety assurance.

Shock Absorbers: The rope design should include shock absorbers, such as shock absorbers, to reduce the impact force during a fall and minimize harm to the human body.

Standards Certification

International Standards: The design of safety belts and ropes should comply with international standards such as ISO 10333 (personal protective equipment for fall protection) and EN 361 (full body harnesses).

National Standards: At the same time, they should meet the relevant standards of the country where they are used, such as the ANSI Z359 standard in the United States.

Static Testing

Tensile Testing: Conduct static tensile tests on safety belts and ropes to ensure that they do not break or deform when subjected to specified loads. The test equipment should simulate actual usage conditions to ensure the reliability of the test results.

Dynamic Testing

Fall Testing: Simulate high-altitude falls to conduct dynamic tests on protective equipment. Attach a test dummy (such as a manikin) to the safety belts and ropes and drop it from a certain height, record the impact force and stress on the equipment, and evaluate its protective effect.

Repeated Fall Testing: Conduct multiple fall tests to evaluate the performance changes of the equipment after multiple uses and ensure its reliability in long-term use.

Environmental Testing

Weather Resistance Testing: Test the protective equipment under different environmental conditions, such as high temperature, low temperature, humidity, and UV radiation, to evaluate its performance under various harsh conditions.

Chemical Resistance Testing: Test the performance changes of the equipment after exposure to chemicals (such as oils, solvents, etc.) to ensure its reliability in chemical hazardous environments.

Tags:

Shanghai C&G's personal protective clothing and PPE products are trusted by customers in the world. Our products are exported worldwide, with a strong presence in the United States, China, Japan, Germany, the United Kingdom, India, France, Italy, Brazil, and Canada. In addition, we have a significant customer base in other countries across each continent, including Australia, New Zealand, South Africa, Nigeria, and Egypt in Africa; Argentina, Chile, and Mexico in South America; Russia, South Korea, and Indonesia in Asia; Spain, Poland, and Turkey in Europe; and Saudi Arabia and the United Arab Emirates in the Middle East. Wherever you are in the world, we have the products you need to stay safe and protected. Contact us today to learn more about our products and how we can help you meet your safety needs.

© 2023 Shanghai C&G. All Rights Reserved.