Characteristics and precautions for use of insulating rods

Insulating rods, also known as link rods, operating rods or insulating pull rods, are commonly used insulating tools in power work. It is mainly used to close or open high-voltage disconnectors, install and remove portable grounding wires, and perform measurements and tests. The following is a detailed analysis of the characteristics of insulating rods and precautions for use:

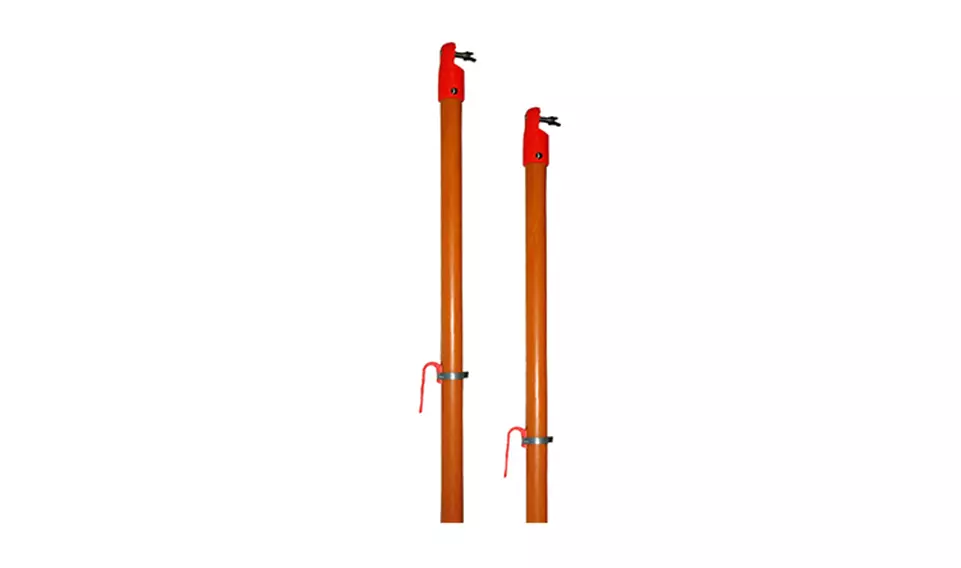

Characteristics of insulating rodsStructural composition: Insulating rods are usually composed of three parts: working head, insulating rod and handle. This design makes the insulating rod have sufficient insulation performance and easy to operate.

Excellent material: Insulating rods are mostly made of materials such as glass fiber and epoxy resin. These materials have good insulation performance and mechanical strength, which can ensure safety and reliability in power work.

Various types: According to the use and characteristics, insulating rods can be divided into many types, such as supporting insulating rods, probe insulating rods, sliding insulating rods and scale insulating rods. These different types of insulating rods play different roles in power work.

Safe and efficient: The design of the insulating rod fully considers safety, and its insulation performance can effectively prevent the occurrence of electric shock accidents. At the same time, the use of insulating rods also improves the efficiency of power work, allowing electricians to complete various operations more quickly and accurately.

Easy to carry: Insulating rods are usually designed to be lightweight, which is convenient for electricians to use when working on site. In addition, some insulating rods also adopt a telescopic design, which can be telescopically positioned according to the needs of the use space, further improving its portability.

Precautions for useAppearance inspection: The insulating operating rod must be inspected before use to ensure that there is no external damage such as cracks and scratches on its surface, as well as moisture and dirt.

Verification and qualification: The insulating rod must be put into use only after passing the test, otherwise it must not be used. At the same time, the insulating rod must be regularly subjected to AC withstand voltage test to ensure that its insulation performance meets the requirements.

Voltage level matching: The specifications of the insulating rod must be suitable for the voltage level of the operating equipment, and it can only be used after verification.

Environmental adaptability: When operating outdoors in rainy and snowy weather, a special insulating operating rod with a rain and snow cover should be used to ensure that its insulation performance is not affected.

Operation specification: When connecting the sections of the insulating operating rod, it should be kept off the ground to prevent weeds, soil or sand from entering the thread or adhering to the surface of the rod. The thread should be tightened gently, and it should not be used without tightening the thread. At the same time, try to reduce the bending force on the rod body during operation to prevent damage to the rod body.

Personal protection: When using the insulating rod, you should wear personal protective equipment such as insulating shoes and gloves to improve the insulation performance and prevent leakage current from harming the human body.

Storage and maintenance: After use, the stains on the surface of the insulating rod should be wiped clean in time, and the various parts should be disassembled and put into a special tool bag, and stored on a well-ventilated, clean and dry bracket indoors or hung up, try not to get close to the wall to prevent moisture from damaging its insulation performance.

In summary, the insulating rod has an important role and wide application value in power work. When using the insulating rod, you must strictly abide by the relevant operating procedures and precautions to ensure the safety and smooth progress of power work.